Key Features

Precision Bonding

Eco-Friendly Solutions

Customizable Adhesives

Global Standards Compliance

Yatomibond

Our Solutions

Yatomibond ensures our labels stay put even in humid conditions, reducing rework and improving reliability. Highly recommended!

Mark T

Operations Manager

Yatomibond’s quick setting and durability have streamlined our mattress production while ensuring top quality. A game-changer!

Sophia L.

Manufacturing Director

Yatomibond provides excellent flexibility and lasting hold, boosting our shoe quality and reducing waste. Fantastic solution!

Cloe Went

Production Manager

Section 1: Frequently Asked Questions (FAQs)

Common questions and answers to help you get started:

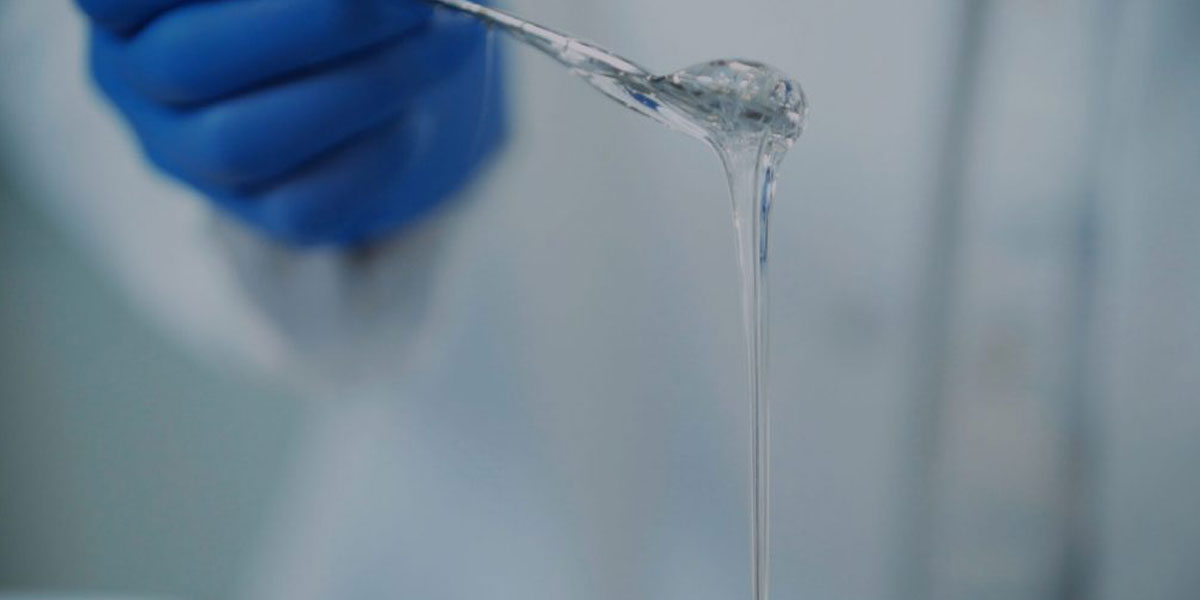

Always refer to the technical data sheet (TDS) for your product. Generally, adhesives should be heated to 350ºF across the glue pot, hoses, and nozzles.

Start with a thin bead of glue and gradually increase the amount until issues like pop opens are resolved. This ensures you use just enough glue to save costs while maintaining quality.

- Stringing happens when the glue is too cold. Check and adjust:

- Glue gun and hose temperatures.

- Nozzle distance from the substrate.

- Yes, adhesive selection depends on your substrates. For example:

- Recycled paper may require specialized adhesives due to shorter fibers.

- Coated plastics may affect adhesion. Share details with us for tailored recommendations.

Knowledge

Ask us every thing you need to know about adhesive